Why Skill Matters When Paying for a Diagnosis

2023 Jeep Gladiator Rubicon: Customer Complaint was ABS and Traction Control Lights Were On

Technician notes:

"ABS light inspection, checked for codes, found multiple codes stored in various modules, uploaded pictures of codes, checked for connection issues in front right wheel speed sensor, checked terminal tension, checked voltage, found low voltage at wheel speed sensor connector, performed visual inspection of abs harness wire loom, removed and inspected ABS module connector, checked terminal tension, performed continuity test between abs module and wheel speed sensor, no concerns found, recommend additional diag time to further evaluate concern."

Summary:

After the initial inspection, the technician confirmed the ABS concern was real (multiple stored codes) and narrowed the problem to the front right wheel speed sensor circuit due to low voltage at the sensor connector. With terminal tension, connector condition, and basic continuity checks not showing an obvious fault, the likely causes at that stage included:

- a failing ABS module,

- a tone ring issue,

- an incorrect air gap between the sensor and tone ring,

- damage within the wiring harness, or

- a bad wheel speed sensor (noting it had been replaced previously by another shop).

Because there were no clear visual issues and the goal was to avoid guessing or replacing parts by trial-and-error, the technician moved to a deeper, test-driven diagnostic approach.

Technician notes:

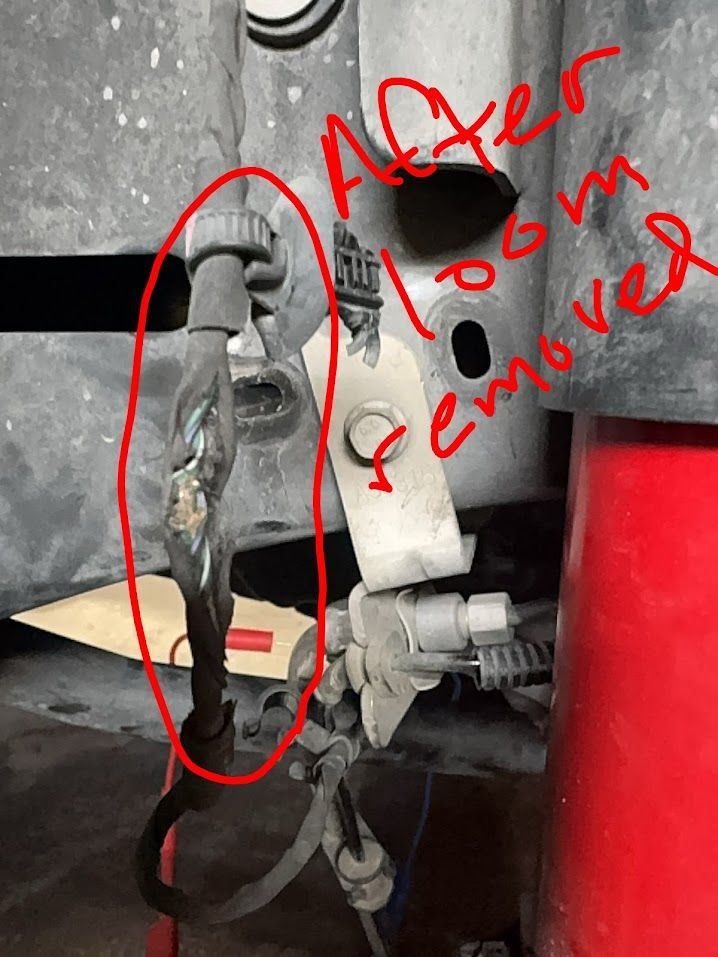

"Additional diagnostic time for Front wheel speed sensor concern, removal of components to gain access to parts of wire harness and perform more test to verify integrity. Performed circuit checks, continuity checks show wires are shorting together, opened wire harness around prone to damage areas near frame, found broken wires causing short in front wheel speed sensor circuit causing low voltage to sensor, performed harness repair, insulated repair connection from elements to ensure proper voltage across wiring, performed voltage test at wheel speed sensor connector, re-established proper voltage to sensor, cleared codes, road tested vehicle, concern solved."

Summary:

One key factor was the vehicle’s oversized tires (37x12.50R17) and occasional rubbing. Since the front right wheel speed sensor wiring runs from the module at the driver-side engine bay, routes around the rear of the firewall, and then into the right wheel well, the technician suspected the harness could be getting contacted or stressed in that area.

To prove or disprove that, the technician performed circuit checks on the harness and physically manipulated (“massaged”) sections where rubbing or chafing would be most likely. After removing the protective loom/sheath in the prone-to-damage area, the technician found damaged/broken wiring consistent with the photo, which explained the shorting condition and the low voltage at the sensor. Once the harness was repaired and protected, proper voltage was restored, codes were cleared, and the road test confirmed the issue was resolved.

Book Now - https://www.chucks-garage.com/killeen-auto-services/computer-diagnostics?mg_show=true